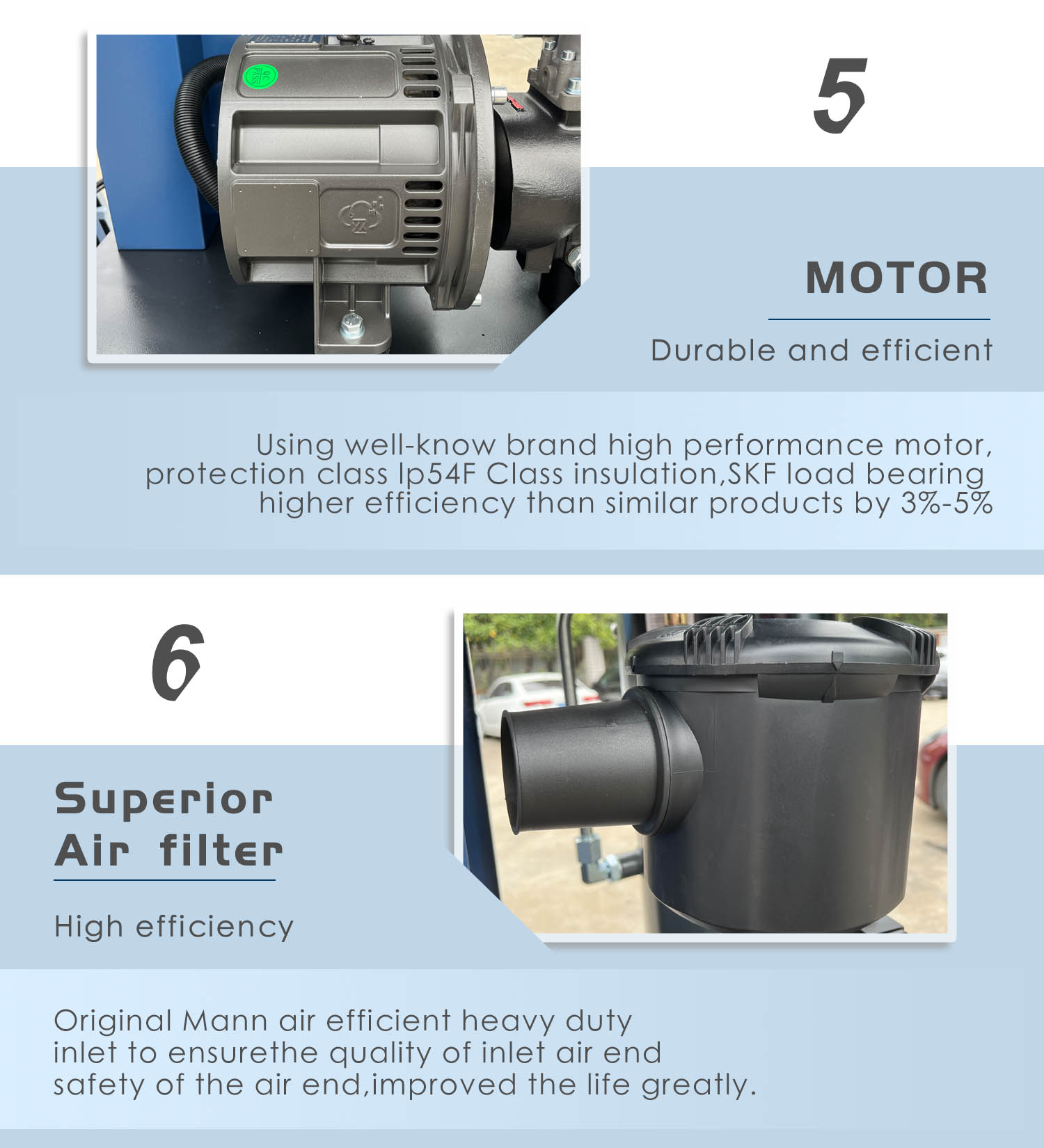

The permanent magnet motor has higher energy efficiency,saves your electricity, IP54, B-level temperature rise is suitablefor heavy dust, high temperature and other harsh environments.

Multiple noise reduction design, calculated according tonoise theory, with special flame retardant muffler cottoninside to reduce unit noise and provide a quieter environment.

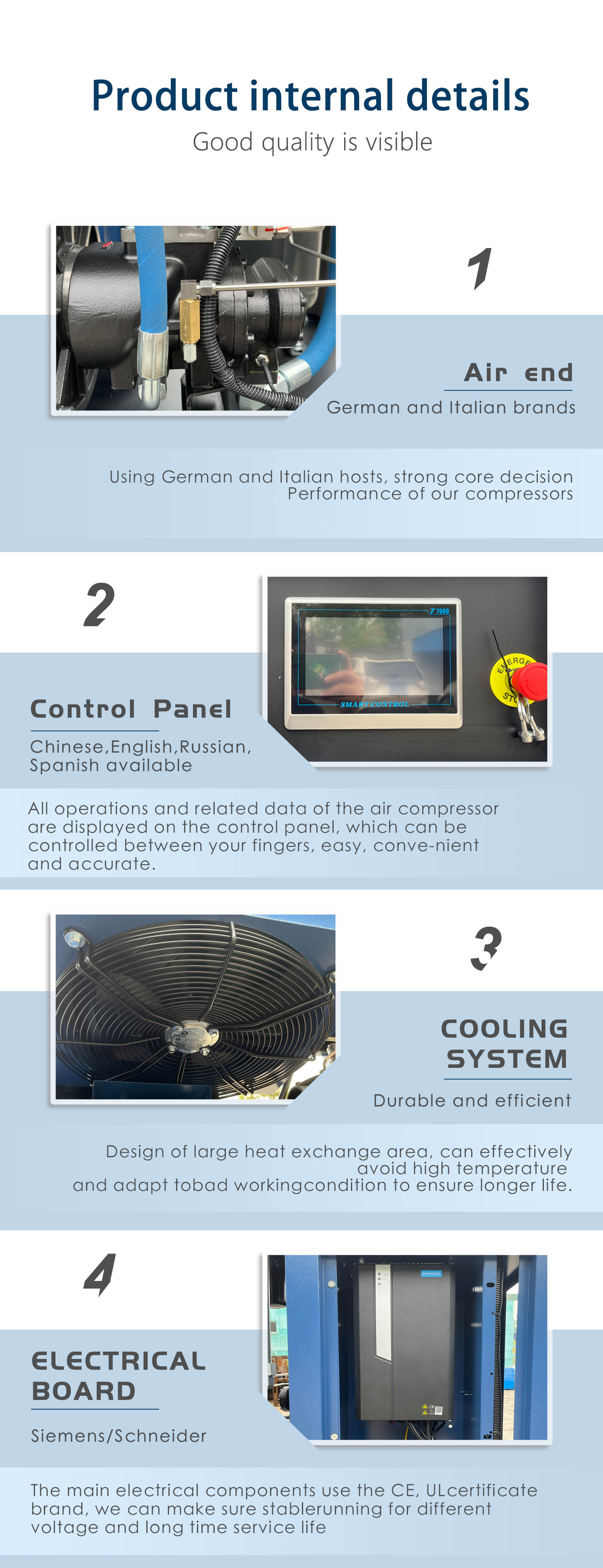

Integrated cooler integrates oil cooling and after cooling.Adopt high-efficiency and low-noise internal rotor axialfan, with large cooling air flow, low noise, faster coolingeffect,and convenient cleaning and maintenance.

Intelligent frequency conversion technology, energy saving up to42%. With the variable speed system, the out put pressure of thecompressor can perfectly match with the demand of the system.which avoid no-load energy consumption. Under the inconstantair demand, frequency conversion system can start without peakcurrent, which avoids the overload and allows the compressor tostop frequently

PM VSD Screw Air Compressor | 30% Energy Saving | 100HP Industrial Grade

Product Image

Product Features

Details

Motor Efficiency Class: IE5/IE4/IE3/IE2 as per your required

Motor Protection Class: IP23/IP54/IP55/IP65 as per your required

Type of Driving: Direct/Belt driven

Type of Cooling: Air Cooling/Water Cooling

GTA means Fixed speed Direct Driven,GTA-5.5 5.5 means 5.5 HP

GTA-PM means Permanent Magnetic Variable Speed.

|

MODEL |

MAXIMUM WORKING PRESSURE |

FREE AIR DELIVERY* OF UNIT AT WORKING PRESSURE |

MOTOR |

NOISE LEVEL** |

AIR OUTLET DISCHARGE SIZE |

WEIGHT |

DIMENSIONS |

||||

|

Bar |

PSI |

l/s |

m3/min |

CFM |

kW |

HP |

KG |

L X W X H (mm) |

|||

|

GAT- |

8 |

116 |

10 |

0.60 |

21 |

4 |

5.5 |

63±2 |

G3/4 |

190 |

820 x 730 x 880 |

|

10 |

145 |

7 |

0.42 |

15 |

|||||||

|

GAT- |

8 |

116 |

14 |

0.85 |

30 |

5.5 |

7.5 |

68±2 |

G3/4 |

280 |

1000 x 735 x 970 |

|

10 |

145 |

11 |

0.64 |

23 |

|||||||

|

13 |

189 |

8 |

0.45 |

16 |

|||||||

|

GAT- |

8 |

116 |

18 |

1.10 |

39 |

7.5 |

10 |

68±3 |

G3/4 |

300 |

1000 x 735 x 970 |

|

10 |

145 |

15 |

0.90 |

32 |

|||||||

|

13 |

189 |

12 |

0.70 |

25 |

|||||||

|

GAT- |

8 |

116 |

30 |

1.80 |

64 |

11 |

15 |

70±3 |

G1 |

330 |

1160 x 786 x 1000 |

|

10 |

145 |

25 |

1.50 |

54 |

|||||||

|

13 |

189 |

18 |

1.10 |

39 |

|||||||

|

GAT- |

8 |

116 |

38 |

2.30 |

82 |

15 |

20 |

70±3 |

G1 |

330 |

1160 x 786 x 1000 |

|

10 |

145 |

30 |

1.80 |

64 |

|||||||

|

13 |

189 |

23 |

1.40 |

50 |

|||||||

|

GAT- |

8 |

116 |

48 |

2.90 |

104 |

18.5 |

25 |

72±3 |

G1 |

600 |

1300 x 900 x 1160 |

|

10 |

145 |

38 |

2.30 |

82 |

|||||||

|

13 |

189 |

30 |

1.80 |

64 |

|||||||

|

GAT- |

8 |

116 |

55 |

3.30 |

118 |

22 |

30 |

72±3 |

G1 |

630 |

300 x 900 x 1160 |

|

10 |

145 |

48 |

2.90 |

104 |

|||||||

|

13 |

189 |

35 |

2.10 |

75 |

|||||||

|

GAT- |

8 |

116 |

78 |

4.70 |

168 |

30 |

40 |

72±3 |

G1 1/2 |

800 |

1580 x 1080 x 1330 |

|

10 |

145 |

72 |

4.30 |

154 |

|||||||

|

13 |

189 |

58 |

3.50 |

125 |

|||||||

|

GAT- |

8 |

116 |

103 |

6.20 |

221 |

37 |

50 |

72±3 |

G1 1/2 |

870 |

1580 x 1080 x 1330 |

|

10 |

145 |

87 |

5.20 |

186 |

|||||||

|

13 |

189 |

73 |

4.40 |

157 |

|||||||

|

GAT- |

8 |

116 |

108 |

6.50 |

232 |

45 |

60 |

72±3 |

G1 1/2 |

950 |

1580 x 1080 x 1330 |

|

10 |

145 |

87 |

5.20 |

186 |

|||||||

|

13 |

189 |

75 |

4.50 |

161 |

|||||||

|

GAT- |

8 |

116 |

162 |

9.70 |

346 |

55 |

75 |

75±3 |

G2 |

1550 |

1800 x 1400 x 1660 |

|

10 |

145 |

123 |

7.40 |

264 |

|||||||

|

13 |

189 |

107 |

6.40 |

229 |

|||||||

|

GAT- |

8 |

116 |

210 |

12.60 |

450 |

75 |

100 |

75±3 |

G2 |

1668 |

1800 x 1400 x 1660 |

|

10 |

145 |

183 |

11.00 |

393 |

|||||||

|

13 |

189 |

157 |

9.40 |

336 |

|||||||

|

GAT- |

8 |

116 |

258 |

15.50 |

554 |

90 |

125 |

75±3 |

G2 |

2480 |

2000 x 1540 x 1800 |

|

10 |

145 |

208 |

12.50 |

446 |

|||||||

|

13 |

189 |

183 |

11.00 |

393 |

|||||||

|

GAT- |

8 |

116 |

325 |

19.50 |

696 |

110 |

150 |

83±3 |

DN65 |

2570 |

3000 x 1550 x 1800 |

|

10 |

145 |

267 |

16.00 |

571 |

|||||||

|

13 |

189 |

233 |

14.00 |

500 |

|||||||

|

GAT- |

8 |

116 |

372 |

22.30 |

796 |

132 |

175 |

83±3 |

DN65 |

2770 |

3000 x 1550 x 1800 |

|

10 |

145 |

325 |

19.50 |

696 |

|||||||

|

13 |

189 |

267 |

16.00 |

571 |

|||||||

|

GAT- |

8 |

116 |

458 |

27.50 |

982 |

160 |

250 |

85±3 |

DN80 |

3120 |

3500 x 1900 x 2000 |

|

10 |

145 |

405 |

24.30 |

868 |

|||||||

|

13 |

189 |

367 |

22.00 |

786 |

|||||||

|

GAT- |

8 |

116 |

700 |

42.00 |

1500 |

250 |

350 |

87±3 |

DN100 |

5600 |

3600 x 2000 x 2050 |

|

10 |

145 |

625 |

37.50 |

1339 |

|||||||

|

13 |

189 |

550 |

33.00 |

1179 |

|||||||

Specifications are subject to change without notice.