Refrigerated Air Dryer | Kill Moisture, Save YOUR Machinery | 3°C Dew Point Dryer | 40% Energy Cut

OUR DRYER DEFENDS YOUR OPERATION:

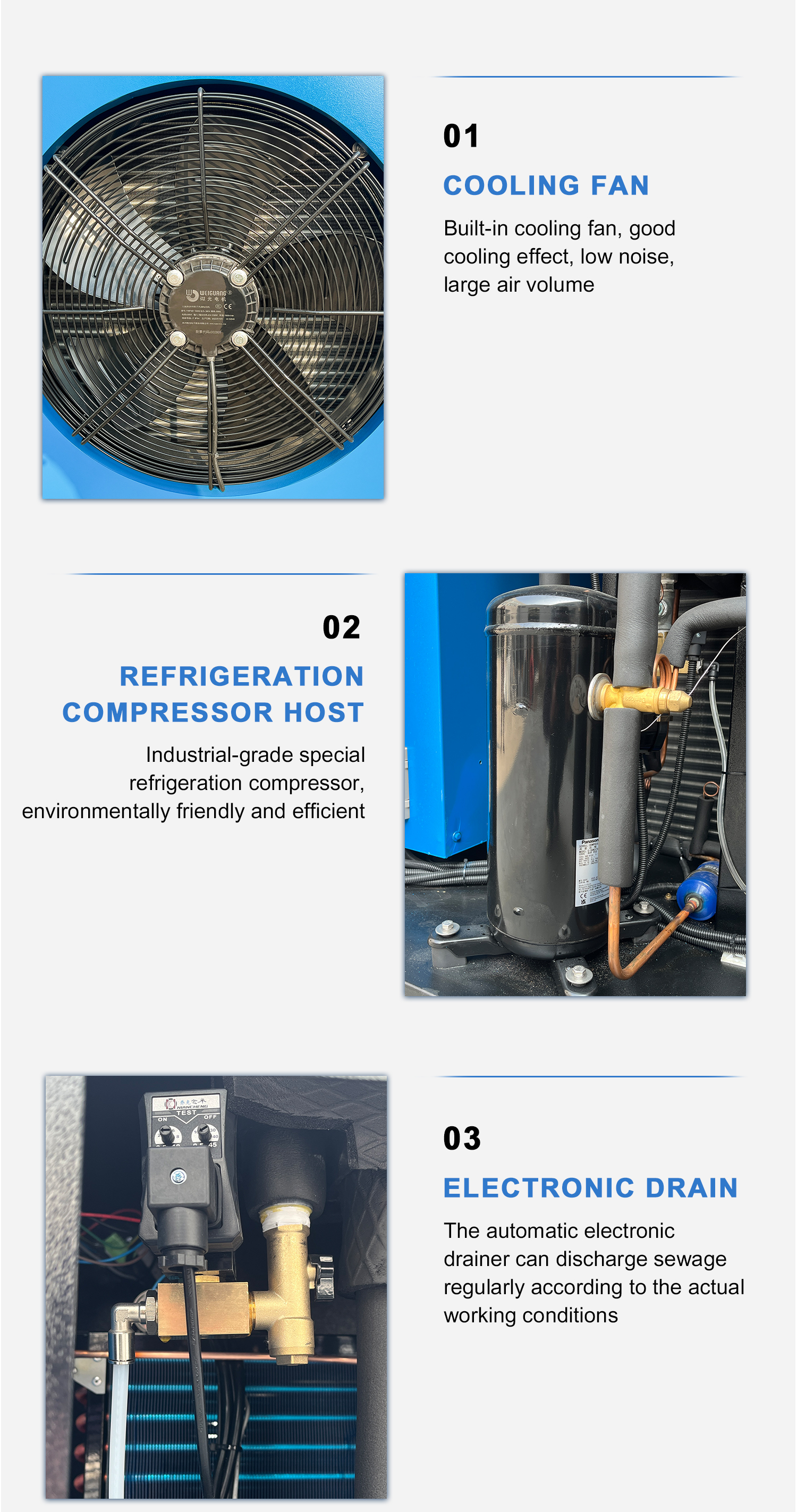

Product Details

Product Details

Product Parameters

Compressed air intake temperature correction coefficient table C1

|

Intake air temperature (℃) |

32 |

35 |

38 |

40 |

42 |

45 |

50 |

55 |

60 |

|

Correction factor |

1.53 |

1.39 |

1.25 |

1.2 |

1.06 |

1 |

0.83 |

0.68 |

0.58 |

Intake pressure correction coefficient table C2

|

Inlet pressure (MPa) |

0.4 |

0.5 |

0.6 |

0.7 |

0.8 |

0.9 |

1.0 |

|

Correction factor |

0.76 |

0.86 |

0.93 |

1 |

1.04 |

1.07 |

1.12 |

Pressure dew point correction factor C3

|

Pressure dew point (℃) |

3 |

7 |

10 |

|

Correction factor |

0.7 |

0.85 |

1.00 |

Ambient temperature correction factor C4

|

Ambient temperature (℃) |

25 |

30 |

35 |

38 |

40 |

45 |

|

Correction factor |

1.10 |

1.06 |

1.03 |

1.00 |

0.96 |

0.71 |

* The air flow under different working conditions can be obtained by multiplying the nominal flow in the specification parameter table by the correction coefficient, the actual drying capacity = nominal flow * (coefficient C1 * coefficient C2 * coefficient C3 * coefficient C4)

Specifications Of Air-Cooled Refrigeration Dryer

|

TYPE |

AIR handling |

refrigeration |

power supply |

INLET/OUTLET |

Dimensions(mm) |

Matched air |

weight(kg) |

||

|

length |

width |

height |

|||||||

|

RD-015 |

1.5 |

0.59 |

220 |

G1" |

730 |

420 |

770 |

7.5 |

61 |

|

RD-020 |

2 |

0.59 |

220 |

G1" |

730 |

420 |

770 |

11 |

61 |

|

RD-026 |

2.6 |

0.75 |

220 |

G1" |

730 |

420 |

800 |

15 |

68 |

|

RD-038 |

3.8 |

0.88 |

220 |

G1-1/2" |

780 |

540 |

1010 |

22 |

102 |

|

RD-069 |

6.9 |

1.24 |

220 |

G1-1/2" |

1000 |

540 |

1010 |

37 |

138 |

|

RD-110 |

11.0 |

1.73 |

220 |

G2" |

1240 |

650 |

1140 |

55 |

205 |

|

RD-140 |

14.0 |

2.6 |

380 |

G2-1/2" |

1240 |

650 |

1140 |

75 |

215 |

|

RD-180 |

18.0 |

2.8 |

380 |

G2-1/2" |

1400 |

700 |

1260 |

90 |

283 |

|

RD-220 |

22.0 |

3.0 |

380 |

DN80 |

1450 |

700 |

1340 |

110 |

324 |

|

RD-280 |

28.0 |

3.75 |

380 |

DN80 |

1450 |

700 |

1340 |

150 |

358 |

|

RD-320 |

32.0 |

4.66 |

380 |

DN80 |

1550 |

750 |

1400 |

160 |

408 |

|

RD-380 |

38.0 |

6.49 |

380 |

DN100 |

1900 |

950 |

1620 |

200 |

585 |

|

RD-460 |

46.0 |

8.85 |

380 |

DN100 |

1900 |

950 |

1620 |

250 |

630 |

|

RD-550 |

55.0 |

9.98 |

380 |

DN125 |

2100 |

1000 |

1790 |

315 |

815 |

|

RD-670 |

67.0 |

10.5 |

380 |

DN150 |

2100 |

1400 |

2000 |

355 |

1106 |

|

RD-750 |

75.0 |

11.25 |

380 |

DN150 |

2100 |

1450 |

2150 |

400 |

1223 |

|

RD-850 |

85.0 |

13.5 |

380 |

DN150 |

2100 |

1450 |

2250 |

450 |

1685 |