Factory Customized Industrial Equipment 300L 500L 1000L High Quality Wholesale Air Receiver Compressed Air Tank Buffer Tank

Product Image

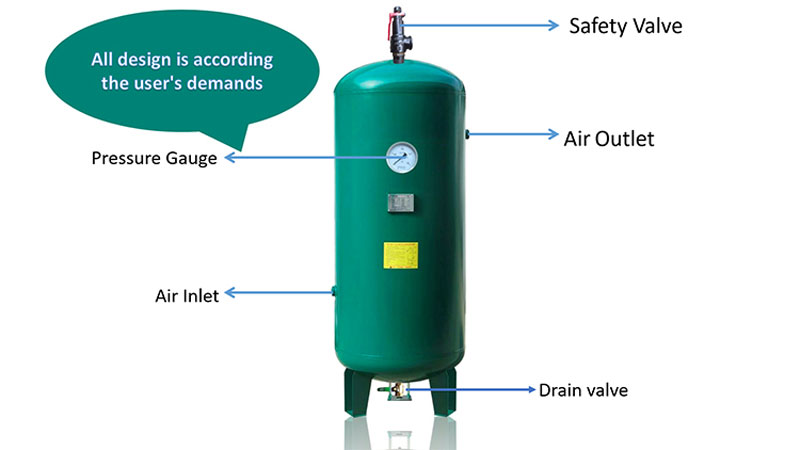

Store Compressed Air

Providing temporary storage space for compressed air is the most important role of the air tank. The air compressor is just a device that compresses air, and there is no space for storing air inside itself. Once the compressed air is generated, it must be discharged to the outside, otherwise it will affect the action of the next compression cycle.

However, in the normal production process, compressed air is not always required, and once unloaded, when compressed air is needed downstream, there will be a delay in reloading and producing air. However, if an air storage tank is configured, even when the air compressor is not running, the air stored in the tank can still be used for a period of time without delaying the production gas.

Conversely, without an air receiver, over time, frequent loading and unloading will lead to premature failure of switches and other compressor components, excessive motor contactor wear, and even a direct short circuit to the motor due to damaged winding insulation.

Stabilize Air Pressure

Without a gas storage tank, uneven end demand would result in frequent loading and unloading of air compressors to meet changing gas demand. The air compressor is affected by various factors such as temperature, voltage, pipeline, etc., the air pressure is not always stable during operation, especially the reciprocating piston compressor, etc., often produce obvious air pressure fluctuations under some working conditions. Equipped with a gas storage tank, the compressed gas has a buffer space, which can effectively reduce the loading and unloading frequency of the air compressor and the pulsation of the gas in the pipeline, and control the system air pressure within the ideal value range.

Cooling And Purifying

The water vapor contained in the atmosphere is sucked into the air compressor for compression along with other air. If it is not removed, the water vapor will condense into liquid water in the pipelines and equipment tools leading to the gas end, which will bring the production system very troublesome. Therefore, the compressed air discharged from the air compressor must be cooled and dried before use. The air tank acts as a storage device. When the air stays in the tank or flows slowly through it, it will naturally cool down over time, and condensate water will be precipitated. The precipitated liquid condensate and the oil vapor condensed into oil, particulate impurities and other mixtures will be collected at the bottom of the tank and discharged.

FUNCTIONALITIES

Suitable for any application using compressed air

• Storage function in order to handle high air consumption

• Stabilize pressure peaks and provide a stable air flow

• Perform a preliminary separation and removal of condensate

Advantage

Reduce compressed air temperature

Store and stabilize compressed air

Optimize energy usage

Remove moisture from compressed air

Lower cycle counts