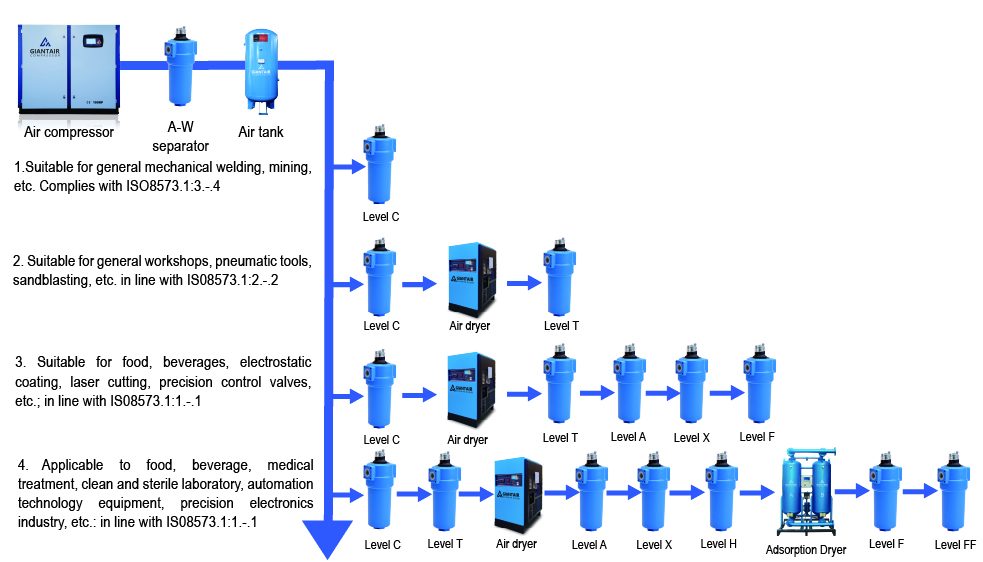

Factory Direct Selling Air Compressor Post-Treatment Pipeline Filters 10bar 30bar 40bar C/T/A/Aa/H Grade Precision Filters

Represents the filter level

Level C filtration accuracy: 3 microns, oil content: 3 ppm.

Level T filtration accuracy: 1 micron, oil content: 1 ppm.

Level A filtration accuracy: 0.01 micron, oil content: 0.01 ppm.

Level X filtration accuracy: 0.01 micron, oil content: 0.003 ppm.

Level H (activated carbon) filtration accuracy: 0.01 micron.Oil content: 0.001ppm.

Level F high efficiency dust removal: filtration accuracy 0.1micron.

Level FF super efficient dust removal: filtration accuracy 0.01 micron

Product Image

Specification

GiantAir air filter grade is divided into C, T, A, AA, H.

C: Filter out liquid and solid particles above 3 microns.

T: Filter out liquid and solid particles above I microns.

A: Filter out liquid and solid particles above 0.01 microns .

AA: Filter out liquid and solid particles above 0.01 microns and 99.999% oil mist of liquid particles.

H: Filter out residual oil vapors and other odors in compressed air.

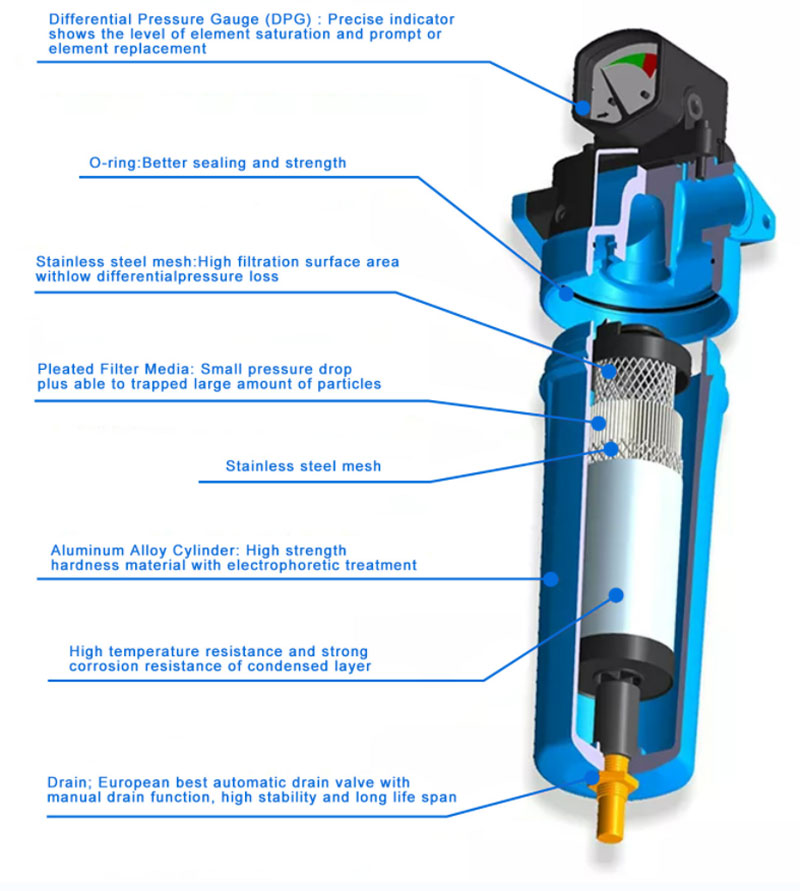

Working Conditions And Technical Data

• Capacity:1.2~25m³/min

• Max. pressure:16bar

• Max.working temperature:80℃

• Differential pressure:0.07bar

• Filter element service:6000hours

• Option choose Air filter with differential pressure indicator and sight glass

• Filter housing internal with anti-corrosion treatment.

Product Parameter Table

| Filter model | Flow m³/min |

Interface c | Type of filter element | H | W | A | B | |

| Product selection | ||||||||

| CJ-005 | 0.7 | 1/2" | FJ-005 | 165 | 74 | 22 | 42 | |

| CJ-010 | 1.2 | 1/2" 3/4" 1" | FJ-010 | 240 | 95 | 32 | 51 | |

| CJ-020 | 2.3 | 1/2" 3/4" 1" | FJ-020 | 280 | 95 | 32 | 51 | |

| CJ-030 | 3.5 | 1-1/2" | FJ-030 | 302 | 125 | 38 | 65 | |

| CJ-050 | 5.7 | 1-1/2" | FJ-050 | 421 | 125 | 38 | 65 | |

| CJ-070 | 7.8 | 1-1/2" | FJ-070 | 421 | 125 | 38 | 65 | |

| CJ-110 | 11.6 | 2" | FJ-110 | 550 | 170 | 46 | 82 | |

| CJ-150 | 15.5 | 2" | FJ-150 | 550 | 170 | 46 | 82 | |

| CJ-200 | 20.8 | 2-1/2" | FJ-200 | 640 | 205 | 60 | 100 | |

| CJ-250 | 25.3 | 2-1/2" | FJ-250 | 640 | 205 | 60 | 100 | |

| CJ-300 | 30.8 | 3" | FJ-300 | 792 | 205 | 60 | 100 | |

| CJ-400 | 40.5 | 4" | FJ-400 | 820 | 220 | 85 | 110 | |

| External flange | ||||||||

| Filter model | Flow m³/min |

Interface | Type of filter element | H | W | A | B | |

| FCJ-200 | 20.8 | DN65 | FJ-200 | 640 | 438 | 92.5 | 92.5 | |

| FCJ-250 | 25.3 | DN65 | FJ-250 | 640 | 438 | 92.5 | 92.5 | |

| FCJ-300 | 30.8 | DN80 | FJ-300 | 792 | 205 | 99.5 | 99.5 | |

| FCJ-400 | 40.5 | DN100 | FJ-400 | 820 | 220 | 150 | 150 | |