Internal Oil Separator:Silent Guardian for YOUR Screw Compressor | 0.5g/m³ Max Oil Carryover | 18-Month Life

OUR SEPARATOR PROTECTS YOUR PROFITS:

Lock Oil in YOUR Crankcase

Nano-coated steel mesh achieves 0.5g/m³ max carryover – 5X below industry standard for your sensitive applications.

Survive YOUR Harshest Shifts

Reinforced epoxy glue endures your 100°C oil temps and vibration. Lasts 8,000 hours – 2X your average unit.

Install During YOUR Coffee Break

Slide-in cartridge replaces your old separator in 15 minutes. Matches Atlas Copco/Sullair ports.

Stop YOUR Contamination Fines

NSF-certified materials keep your air compliant. No more FDA audit panic.

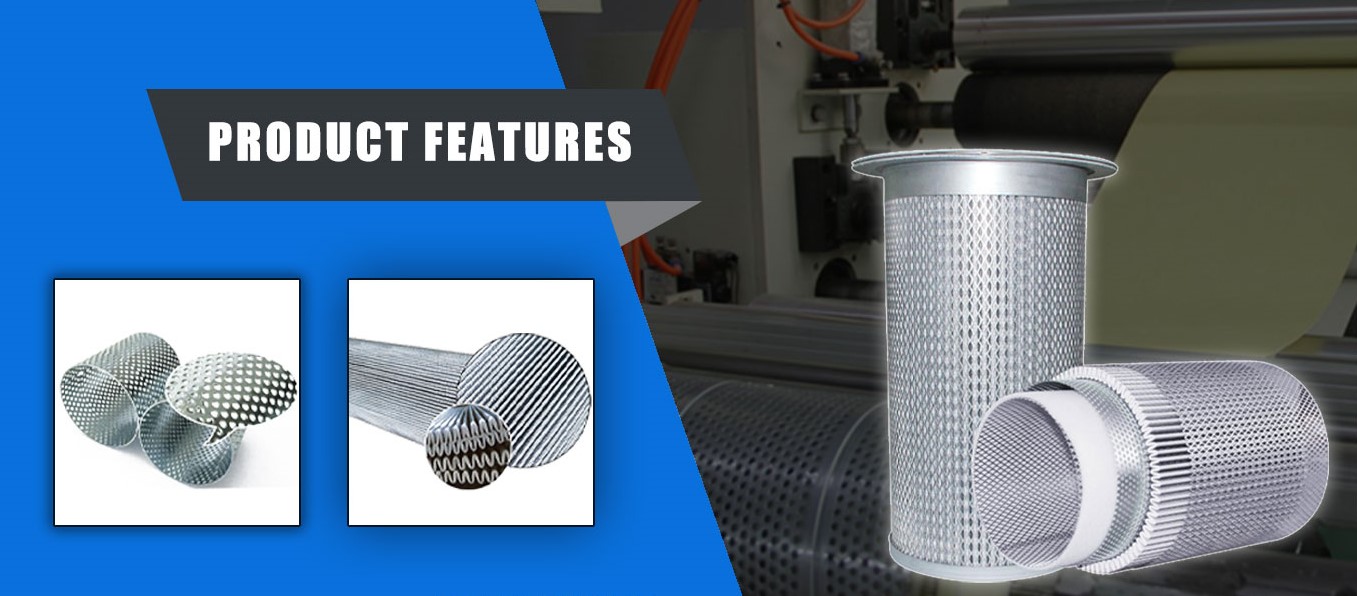

Product Features of GiantAir Oil Separator

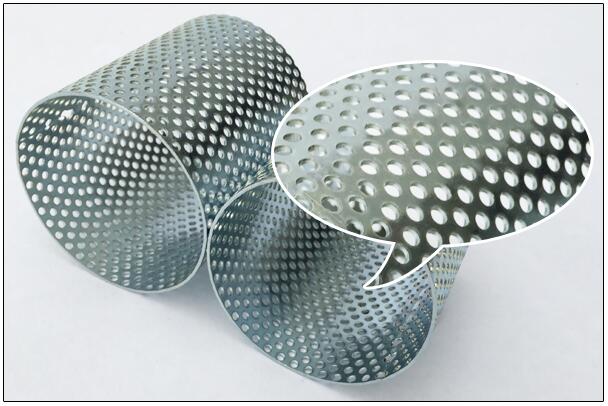

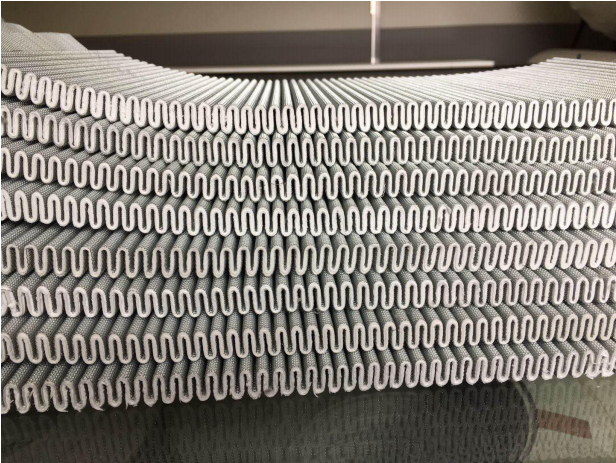

◆The oil and gas separator core adopts imported filter material, which has higher efficiency and longer service life.

◆Larger filter area, less pressure loss.

◆Reduce the loss of lubricating oil, improve the quality of compressed air, prolong the service life, and reduce the cost of machine use.

◆All types of GiantAir oil seperator are same standard and design of the orginal one, to make sure the good quality.

◆We pay attention to every details, we will make the customized label and good quality carton box to make sure the good packing for the oil seperator.

How to replace the built-in oil and gas separator

◆Shut down the air compressor, close the air pressure outlet, open the drain valve, and confirm that there is no pressure in the system.

◆Disconnect the pipeline above the oil and gas tank, and at the same time remove the pressure maintenance valve .

◆Remove the piping from the port to the cooler.

◆Remove the oil return line.

◆Remove the fixing bolts of the cover on the oil and gas tank, and remove the upper cover of the gas tank.

◆Remove the oil and gas separator and replace it with a new one.

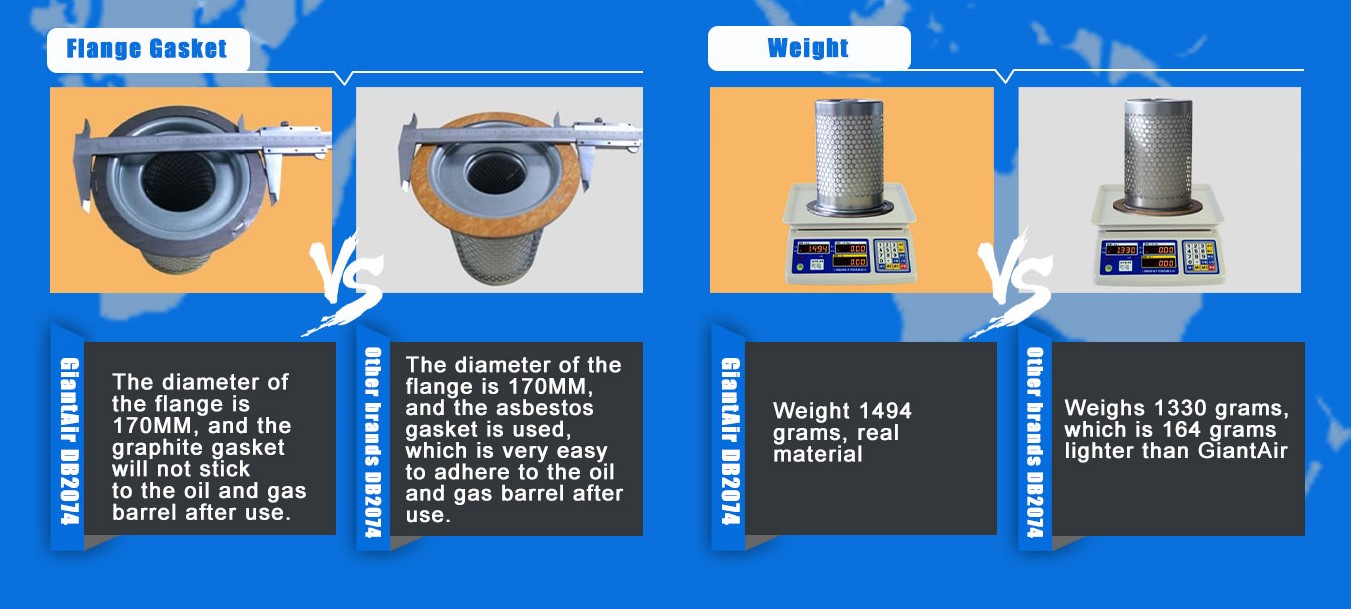

◆The staples on the flange gasket of the oil and gas separation core are static-conducting devices and cannot be removed.

◆Reassemble in the reverse order of disassembly.

◆Please open the air compressor outlet valve before commissioning.

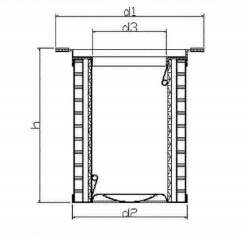

Specification sheet

| Product Model | Corresponding part number |

Rated flow (m3/min) |

法兰d1 (mm) |

外径d2 (mm) |

内径 d3 (mm) |

高度h (mm) |

||||||||

| 99090135 | 99090135 | 1.3 | 116 | 90 | 40 | 135 | ||||||||

| 99135160 | DB2507 | 2.6 | 170 | 135 | 75 | 160 | ||||||||

| 99130203 | DB2074 | 3.9 | 170 | 135 | 75 | 200 | ||||||||

| 99135230 | 99135230 | 5.2 | 170 | 135 | 109 | 230 | ||||||||

| 99165231 | DB2186 | 6.5 | 200 | 170 | 109 | 230 | ||||||||

| 99165305 | DB2132 | 8.9 | 200 | 170 | 220 | 305 | ||||||||

| 33235306 | 91111-003 | 16 | 355 | 300 | 220 | 305 | ||||||||

| 99295401 | 91111-001 | 22 | 355 | 300 | 220 | 400 | ||||||||

| 99295503 | 91111-007 | 28 | 355 | 300 | 220 | 500 | ||||||||

| 99295600 | 91111-008 | 34 | 355 | 300 | 220 | 600 | ||||||||

| 99350550 | 99350550 | 41 | 430 | 350 | 265 | 550 | ||||||||

Technical parameter

| Residual maximum oil content | 3PPM | Max working temperature | 120℃ | ||||||||

| Highest initial pressure drop | 0.02Mpa | Highest pressure diffrence | 5bar |